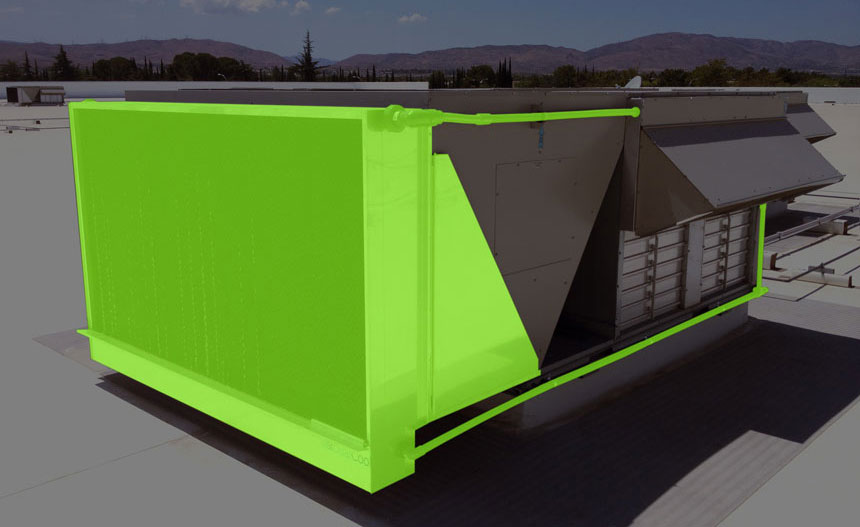

DualCool® was developed as a retrofit solution for commercial roof-top air conditioning units, with two basic goals: reducing peak electrical demand (kW) and reducing electrical energy use (kWh). Integrated Comort Inc. has overachieved both goals with our patented solution. As the name implies, DualCool is providing cooling in two ways: direct evaporative condenser air pre-cooling and indirect cooling of the fresh air stream. The airstream and the water are cooled evaporatively as water flows evenly downward

from the stainless steel reflector above the perforated top distribution pipe. The condenser fans on the rooftop unit cause the air to flow across the media before passing across the condenser coil. A radiator-like heat exchanger cools the fresh air stream required by building codes to maintain indoor air quality in commercial buildings. It is also the feature that distinguishes the patented DualCool product from conventional condenser air pre-coolers.

Schematic

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

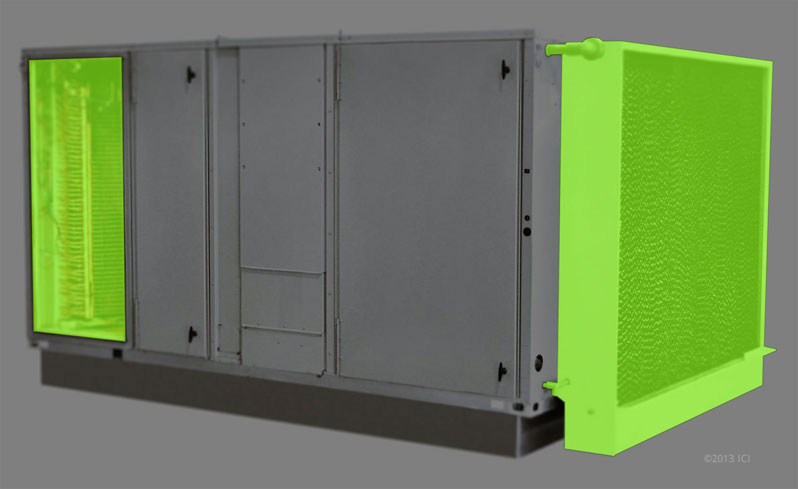

DualCool ® Schematic

The schematic above illustrates the movement of the air, water and refrigerant through a Roof Top Unit with DualCool installed. The DualCool components are shown in green. A description of the DualCool components are provided below. MORE …

Components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-Cooler Enclosure

The major DualCool structural element is its stainless steel sheet metal enclosure that is custom-fit to each rooftop unit. This “unibody” assembly gains its strength from shape and connections rather than from metal thickness. The design facilitates an affordable “lifetime” enclosure that will outlast the rooftop unit to which it is attached. The integral bottom reservoir includes a screened stainless steel top that limits entry of debris, and the reservoir’s smooth flat bottom with rimless drain opening allows easy annual cleaning. On units with inward-slanting condenser coils, the enclosure includes hinged triangular panels that provide easy coil access. The unique design also facilitates easy removal of the evaporative media yet holds the media securely to prevent movement in windy conditions.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Submersible Pump

A submersible pump is the primary operating component in the DualCool system, moving cool water from the reservoir beneath the evaporative media to, and through, the vent air pre-cooling coil, and then back to a distribution tube above the evaporative media. Water flowing through the coil cools the warm incoming fresh air stream, and water flowing by gravity downward through the media cools the air entering the large condenser coil through which refrigerant is discharging heat to the outdoor air. The submersible pump strategy maximizes protection of this vital component, and maintains a clean unit appearance without external components and wires. ICI selected the current pump series for durability and energy efficiency after extensive lab and field testing. Pump access requires no tools; the technician simply pulls outward on the handle of the removable perforated metal media holder above the pump, removing the entire media section.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

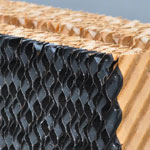

Evaporative Media

If the pump is the heart of the DualCool system, the evaporative media sections are the lungs. These 8” thick blocks of “cross-corrugated” treated cellulose are the highest quality evaporative media available, squeezing near-maximum cooling from the evaporative process. The heavy, dark “edge-coat” that ICI specifies for the media front edge provides protection against UV-degradation and damage from hardness minerals where groundwater is used. Both the airstream and the water are cooled evaporatively as water flows evenly downward from the stainless steel reflector above the perforated top distribution pipe. The condenser fans on the rooftop unit cause the air to flow across the media before passing across the condenser coil. Most media sections are 24” wide to streamline installation and removal. They are grooved at the top for retention against the wind, and are retained at the bottom in a perforated stainless steel tray. Media sections are easily removed for cleaning. The 3 to 7 year media life is mostly variable with hardness mineral content of the water.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation Air Coils

This radiator-like heat exchanger cools the fresh air stream required by building codes to maintain indoor air quality in commercial buildings. It is also the feature that distinguishes the patented DualCool product from conventional condenser air pre-coolers. Cool water is pumped directly from the DualCool reservoir through this efficient coil, typically cooling outdoor air almost to indoor air temperature. The coil uses copper tubes and aluminum fins, and is carefully designed to drain water back to the reservoir when the pump turns off. Water leaving the coil flows to the distribution pipe atop the evaporative media, where it flows downward by gravity through the media to complete the water flow loop.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Controls

The major DualCool control need is a thermostat that activates the pump when outdoor temperature exceeds a preset value (typically 70 to 75 degrees F). Earlier DualCool controls required low voltage power for pump and solenoid refill valve switching. (Since water evaporates to accomplish the cooling task, an automatic system is required to refill the DualCool reservoir.) The current basic DualCool control system relies on a line voltage thermostat and a simple, highly reliable float valve. This system takes advantage of the 115V service receptacle that is typically located in or on the rooftop unit. The DualCool thermostat is located inside the controls cabinet of the rooftop unit, with an external bulb temperature sensor. Like the pump, the float valve is easily accessed by removing a media block and its supporting perforated metal screen at one side of the pre-cooler.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Bleed System

Where the supply water exceeds about 30 PPM of hardness mineral, ICI recommends the optional “bleed” system that limits the concentration of hardness minerals in the DualCool water loop. Without the bleed system, minerals can build up on all surfaces that the water contacts, compromising both appearance and function of the system. ICI technicians and trained DualCool installers measure hardness content of the supply water and specify a bleed rate. A bleed valve is then set to the specified rate. An upstream filter protects the bleed valve against clogging. Cleaning the bleed filter is important to maintaining performance and maximizing media life.

Performance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance

The two basic DualCool performance goals are to:

-

Reduce peak electrical demand (kW)

-

Reduce HVAC electrical energy use (kWh)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Demand Reduction

The economic value of kW demand reduction accrues principally to the electric utility, although “demand,” “time-of-use” and “real-time” rate structures transfer some of the benefits to the customer. DualCool can be installed on most rooftop units at lower “cost per kW” than new generation, while eliminating the new generator’s fossil fuel consumption. DualCool peak demand reduction varies with climate, refrigerant, and ventilation setting. DualCool can also reduce the peak demand of blowers and condenser fans. MORE …

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Energy Savings

DualCool energy savings are more difficult to predict than demand reduction, since energy savings accrue over an entire cooling season. DualCool energy savings are possible in all three “motor sets” in the heating/ventilating/air conditioning (HVAC) unit: the compressor(s), the blower, and the condenser fan(s). The compressor is the driving force in the refrigerant system, the blower moves air across the cooling coil and into the building, and the condenser fan(s) move(s) air across the condenser coil that discharges heat to the outdoors. MORE …

Service & Warranty

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICI prefers to include a prepaid 3-year service and warranty program with each DualCool sold.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Plan

The Service Plan is carried out by trained service crews, includes three scheduled site visits per season:

-

Spring startup: Close supply line drain valves, re-connect supply lines, place drain plugs in reservoirs, turn on main water supply, fill reservoirs, reposition, plug in, and activate pumps, check for leaks, reset bleed valves, verify proper controls operation, complete service checklist.

-

Mid-summer check: Check operation, clean bleed filters, check bleed rates, check media water distribution, wash down reservoirs if necessary, complete service checklist.

-

Fall Shutdown: Remove media and pressure wash if necessary, clean water feed pipe, drain and clean reservoir as necessary, unplug, disconnect and tilt pumps to drain, “blow-down” coil return line, shut off main water supply, open supply line drains, complete service checklist.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty

Within the 3-year warranty period, ICI will replace any defective components at no charge to the customer. As a “wear component” the evaporative media will be replaced if necessary on a pro-rated basis in comparison with its 5 year expected life. The warranty does not cover:

-

Damage to pumps if the water supply has been interrupted by a customer’s agent, or

-

Failure of the evaporative media if a customer’s agent has reduced the required bleed flow rate.

Economics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Economics

Economic analysis of a demand-reducing, energy-saving product like DualCool requires estimates of savings and installed costs. The most typical economic measure is payback: the years required for accumulated savings to exceed accumulated costs, or:

(Net Installed Cost) / (Net Annual Savings)

where Net Annual Savings = Annual (Savings – Water Cost – Maintenance Cost)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .